- Home

- Bob Cashner

The FN FAL Battle Rifle Page 4

The FN FAL Battle Rifle Read online

Page 4

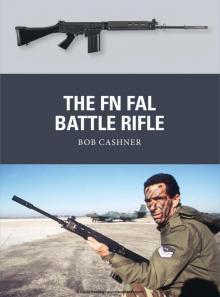

An FN-made ‘paratrooper’ FAL,

IMPROVEMENTS AND MODIFICATIONS

with short barrel, plastic folding

stock and fixed rear sight. (Photo

Addressing the length issue:

courtesy of Rock Island Auction

Company)

folding-stock and specialized versions

One of the FAL’s few faults was its length; the L1A1 in particular, with its 102mm (4in)-long flash suppressor, was 1,143mm (45in) long overall.

This length made it rather unwieldy for small-statured troops such as the Gurkhas, and was less than handy in thick jungle and urban environments.

It also posed a particular problem for mechanized troops riding in armoured personnel carriers (APCs), airmobile units using helicopters, and especially for airborne troops. For example, Belgium’s elite Régiment Para-Commando jumped from Fairchild C-119G ’Flying Boxcar’

transport aircraft, which instead of a folding rear ramp had only a hatch door on either side to dive through. A full-length FAL was a tight squeeze when it came to exiting this door.

These length issues led to the adoption of several specialized FAL

models, including both standard fixed-stock rifles with carbine-length barrels and folding-stock versions with various barrel lengths. The folding-stock carbines became known almost immediately as ‘Para’ or ‘Congo’

models; they included the 50.61 (full-length barrel, standard charging handle), 50.62 (458mm/18in barrel, folding charging handle), 50.63

(406mm/16in barrel, folding charging handle) and 50.64 (full-length barrel, folding charging handle, aluminium-alloy lower receiver). The folding cocking handle of the 50.62, 50.63 and 50.64 models was designed to keep it from protruding when the stock was folded. The ‘Para’ required more than just a folding stock, however. With the standard fixed-stock FAL’s main buffer and spring located in the buttstock, the entire operating system had to be modified, including the receiver, to produce the folding-stock version.

Various military-issue FALs compared

FAL Standard

FAL Standard

FAL Para

FAL Para

FALO LAR

(50.00)

L1A1 SLR

Carbine

(50.61)

Carbine (50.3)

(50.41)

Weight

4.3kg (9.48lb)

4.3kg (9.48lb)

3.8kg (8.4lb)

3.9kg (8.6lb)

3.79kg (8.4lb)

5.95kg (13.1lb)

Barrel length

533mm (21in)

533mm (21in)

436mm (17.2in)

533mm (21in)

436mm (17.2in)

533mm (21in)

Length extended

1,090mm (42.9in) 1,143mm (45in)

993mm (39.1in)

1,095mm (43.1in) 998mm (39.3in)

1,125mm (44.3in)

Length folded

n/a

n/a

n/a

845mm (33.3in)

748mm (29.4in)

n/a

22

© Osprey Publishing • www.ospreypublishing.com

‘Para’ stocks are skeletal and

universally fold forward sideways

against the right side of the receiver.

A rubber buttplate is fitted on some;

quite a few civilian shooters have

acquired a padded cheekpiece of

some kind due to the felt recoil of

the smaller tubular stock against the

face when aiming and firing. Other

users insist that the standard ‘Para’

stock is just fine, requiring only that

one ‘get used to’ the difference.

Problems with desert

conditions: the saga of

the ‘sand cuts’

Although the L1A1 was not yet in

universal service with British forces

during the Suez Crisis of 1956,

reports came back from the field

that the weapon had experienced

numerous malfunctions due to the

sand and dust of Egypt’s desert

environment. The IDF also had

complaints about the FAL’s

performance in the desert. For

British, Indian and Israeli troops

alike, this proved to be a very

serious issue.

Five members of the Nigerian

Extensive testing commenced in search of a solution to this problem. Army establishing a perimeter The tests were particularly harsh and realistic; fine particulate wind-near the old airfield north of

Mogadishu, Somalia, 1993.

blown sand was imported from Egypt for initial experiments at RSAF During the 1980s the state-owned Enfield. By the end of 1955, Britain’s ARDE believed it had come up with Defence Industries Corporation of a cure, in the form of ‘sand cuts’. Rifles modified in this fashion were then Nigeria began licenced production sent to Egypt for further field testing in actual desert conditions. In both of the FAL as the NR-1. The new rifle entered service in 1989.

locations, the rifles were blasted by ‘artificial sandstorm’ equipment and, (US Army) in the latter, actually buried in the sand before firing.

The most obvious difference arising from these modifications can be seen on the exterior of the breech-block carrier – a series of machined cuts at 45-degree angles, taking the shape of ‘WWW’. These ‘inclined scraper recesses’ were intended to remove sand from the action during both forward and backward strokes. The forward ends of the sliding surface were also relieved, and a pair of 30-degree chambers were machined on the inside edges of the carrier.

Similar relief modifications were made to the breech-block and the main slide of the receiver body. These changes, plus the use of graphite grease as a lubricant, appeared to cure what ailed the FAL in sandy and dusty 23

© Osprey Publishing • www.ospreypublishing.com

conditions. The complaints garnered in

the Suez Canal Zone were not evident

when the L1A1 was used in similar

harsh desert environments such as

Muscat and Oman, the Radfan and

Aden, Dhofar and Kuwait (in 1961, the

first time Kuwait’s neighbour Iraq tried

to annex that country). Likewise, the

FAL has since seen service with Bahrain,

Cameroon, Chad, Cyprus, Djibouti,

Liberia, Libya, Morocco, Nigeria,

Qatar, Syria and Yemen.

The Israelis never adopted the

British system of receiver and bolt-

carrier ‘sand cuts’, but did modify the

bolt and bolt handle of their FALs to

An SAS trooper gives medical

make the bolt handle reciprocating. This allowed the bolt handle to be treatment to the villagers of

used as a forward assist to allow the shooter manually to push forward a Falige, in the remote Yanqul

cartridge that had failed to chamber fully.

Plain of Oman. The L1A1’s early

Of course, standard operating procedures were also adapted to address reliability problems in desert

conditions had been remedied by

this issue. The Australian Army’s 1983 SLR manual features four the time of the Oman campaign.

paragraphs regarding care of the weapon in ‘Abnormal Conditions’. The (IWM MH 30626)

second paragraph lists desert conditions: ‘When conditions are dry, sandy or dusty, clean and inspect more frequently to prevent the formation of rust and corrosion. Lubricate sparingly with graphite or light oil and then wipe dry. Wash brushes in soap and water and dry them before use’

(Australian Army 1983: 2-23). They would experience further trouble with the FAL in the desert.

ACCESSORIES

Magazines

There were a variety of

staggered-row detachable box magazines manufactured for the FAL in several countries, with the 20-round magazine being the standard. The two main varieties are ‘Inch’ and ‘Metric’. The was designed specifically for the SLR as used by Britain and the former Commonwealth nations, while the latter was used by countries with Metric-pattern FALs. Inch-pattern SLRs can accept either Inch or Metric magazines, but Metric FALs will only accept Metric magazines.

The vast majority of FAL magazines were made of steel, with the original Belgian FN magazines finished with durable black enamel paint.

Made on FN tooling, the Argentine and Brazilian magazines are nearly identical except for the finish on the magazine follower. Israeli-made magazines are the same, but bear two Hebrew characters stamped into the metal on one side. German G1 magazines, on the other hand, were made of 24

aluminium with differing anodized finishes. While such coatings show wear

© Osprey Publishing • www.ospreypublishing.com

quickly, these magazines were the lightest of the FAL varieties and, as noted, every ounce that can be shaved from the weight of an FAL is desirable.

Turning to Inch-pattern magazines, Canadian- and Australian-

manufactured magazines were unmarked. British-made SLR magazines were stamped with part numbers, year of manufacture and a proof mark.

Although less common, a variety of 30-round magazines were

manufactured for the heavy-barrelled SAW-configured FALs such as the C1A1 or the FAP. The British L4A2 30-round magazine is the most interesting. When Britain’s Mk 3 and Mk 4 Bren guns were converted from .303in British to 7.62×51mm NATO ammunition as part of that weapon’s conversion to the L4 model in 1954, the British modified the curved magazine to fit the SLR too; these magazines also work well in the Canadian FAL variants. Since the Bren fed from the top of the receiver, gravity assisted the feed. Inverted for use in the SLR, the magazine’s springs sometimes proved to be underpowered; this problem was fixed in the field by removing the spring and stretching it. Other SLR

and FAL 30-round magazines, usually unmarked, are Canadian or

Australian-made; they are straight in profile and built with springs designed from the outset to feed upwards.

Sights

Old-fashioned iron sights, with a blade foresight and ‘V’-notch rear sight, require the human eye to focus simultaneously in three planes, which it cannot do. Sight has to be transferred rapidly from one focal point to another. A vast improvement is offered by the aperture or ‘peep-style’

military-rifle sight. When looking through a sizeable rear aperture, the eye naturally centres itself in the opening where the most light is available, so that the shooter need only focus on two planes: the front sight and the target.

The military-issue aperture sights of the FAL and L1A1 are certainly good, but not quite in the same league as those of the M1 Garand and the M14. The standard rear sight is an aperture on a sliding scale graduated from 200m (219yd) to 600m (656yd). It is adjusted for windage via two screws, one on either side of the sight base. The rear-sight assembly itself is not protected from blows by the ‘wings’ or ‘ears’ found on most American rifles.

Another notable improved sight was the British and Commonwealth

‘Hythe Sight’. The rear sight consists of two separate folding stems, each containing a different-sized aperture. For daytime use and long-range accuracy, the front ‘tombstone’ is flipped up, providing a 2mm (0.08in) hole. For night firing and also useful for quick snap-shooting at close range during the day, the smaller aperture is folded down to provide a much larger 7mm (0.28in) aperture.

‘Para’ FALs were equipped with a different sight; a two-position flip sight. The rear sight consisted of two different blades which could be used alternately, a sight with a large aperture zeroed to 150m (164yd) for rapid, close-range work and another blade with a small aperture and graduated for 250m (273yd) for more precise aiming at longer ranges.

25

© Osprey Publishing • www.ospreypublishing.com

THE FAL EXPOSED

7

3

4

5

6

8

1

2

21

20

19

22

24

23

18

17

Operation and function

In its final form, the FAL was a gas-operated tilting-block design breech-block clears the top of the magazine, the spring in the bearing many similarities to the World War II-era Soviet Tokarev SVT-magazine pushes the next loaded round up into position for loading.

40 self-loading rifle. Its operation can be described briefly in two sections covering the backward and forward actions of the mechanism.

The forward action

1. The compressed return spring in the butt expands to push the The backward action

breech-block and slide back into battery. As the breech-block

1. When the trigger is squeezed, it disengages the sear, in turn assembly moves forward, the fresh round from the magazine is

releasing the hammer to strike the end of the firing pin and fire the engaged and fed into the chamber.

cartridge in the chamber.

2. As the breech-block stops its forward movement, the slide

2. As the bullet travels down the barrel, it is driven by expanding continues forward, tilting the breech-block down into the locked gases. A portion of these gases enters a gas vent and passes through position for firing. The rear of the firing pin is exposed and the the gas plug to force the gas piston to the rear. The piston strikes ejector grasps the rim of the chambered cartridge.

the slide and drives it rearward. Once the gas energy is expended, 3. During this forward movement, the safety sear is pushed out of the gas-piston spring forces it back into the forward position.

engagement with the hammer. The hammer then engages the

3. As the slide is driven to the rear, it lifts the tilting breech-block trigger sear and is held there until the trigger is squeezed again.

up out of its locking recesses and to the rear.

4. When the breech-block moves to the rear, the empty cartridge As long as there are fresh cartridges in the magazine, this process case is pulled out of the chamber by the extractor. During rearward will repeat itself every time the trigger is squeezed. On full-movement, the base of the case strikes the ejector and the empty automatic models, the cycle will continue until the trigger is case is ejected from the rifle.

released or the magazine is empty. On ‘Metric’ FALs, the bolt is 5. In the rear position, the slide compresses its return spring, locked to the rear after the last round has been fired.

26

mounted within the buttstock on standard-model FALs. As the

© Osprey Publishing • www.ospreypublishing.com

9

10

11

12

13

14

15

16

British Inch-pattern L23A1 instructional rifle

1. Butt plate

11. Piston

21. Hinge pin

31. Change lever

2. Return spring

12. Gas regulator

22. Pistol grip

32. Trigger spring

3. Rear sight

13. Foresight

23. Butt

33. Trigger plunger

4. Hammer

14. Gas plug

24. Rear sling swivel

34. Trigger

5. Ejector port

15. Flash hider

25. Safety sear

35. Trigger guard

6. Breech block

16. Barrel

26. Cocking lever

36. Sear spring

7. Slide

17. Carrying handle

27. Hammer

37. Sear

8. Top cover

1

8. Magazine

28. Hammer spring

38. Magazine catch

9. Handguard

19. Locking shoulder

29. Body locking catch

39. Holding open catch

10. Piston spring

20. Retaining pin

30. Body locking lever

40. Magazine spring

25

26

28

29

27

31

36

32

30

39

38

27

40

37

33

34

35

© Osprey Publishing • www.ospreypublishing.com

This FN-made FAL is fitted with a

Optics

folding bipod, carrying handle and

One of the main drawbacks in fitting good optics to the FAL was the black composite furniture. Note

design of the removable steel top cover, which was thin and had a the British illuminated scope,

tendency to move slightly on firing, and was unsuited to the fitting of the L2A2 ‘Sight Unit Infantry

Trilux’ (SUIT) – the closest thing

any sight mount that required a high level of accuracy. The introduction to an ‘offical’ FAL scope. (Photo

of stronger covers and the use of side mounts that fitted to the receiver courtesy of Rock Island Auction

of the rifle improved matters, but it was never a particularly outstanding Company)

sniping rifle.

Nevertheless, Fabrique Nationale soon adapted the FAL to take

telescopic sights, calling the weapon so outfitted Le fusil pour tireur d’élite, roughly translated as ‘rifle for elite shooter’. Two types of scope were fitted: the OIP/FAL and the OIP/AFN, both made by Société Belge d’Optiques et d’Instruments de Précision (OIP).

The Belgian scope-mounting system used flexible metal bands

tightened by bolts on a modified FAL dust cover instead of scope rings; this system held the scope low and offset to the left of the bore. The offset scope required a leather cheekpiece fitted to the stock for the shooter to achieve a good cheek weld, similar to the system used with the M1C and M1D sniper versions of the M1 Garand with their offset scope mounting.

Although it was used by the Belgian Army, no other countries adopted it.

If there is an ‘official’ FAL scope, however, it is the Sight Unit Infantry Trilux (SUIT). In an idea rather before its time, the SUIT arose from the British and New Zealand – and later the Israeli – idea to turn the FAL

The FN FAL Battle Rifle

The FN FAL Battle Rifle